-

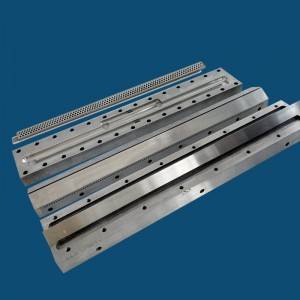

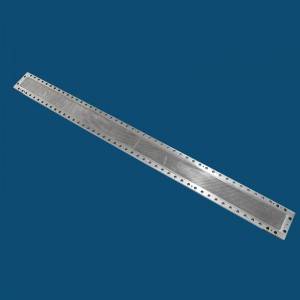

Top Suppliers Meltblown Fabric Making Machine - melt blown spinneret – Shengshuo

melt blown spinneret,has thousands of rounded ultra micro hole,made from forging SUS630 or SUS431,able to produce the fabric which the width from 270-3200mm,diameter can be done from 0.1-0.25mm,L/D from 1:10-1:20. it attaches to the meltblown header,melted material going from the header then through the air duct and the distributor,then going into the spinneret,until to the chemical fiber.it has to be cleaned every 45 days to 60 days. -

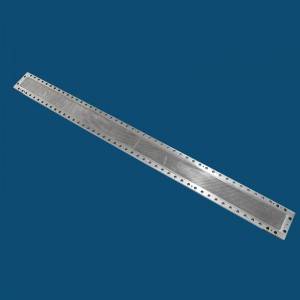

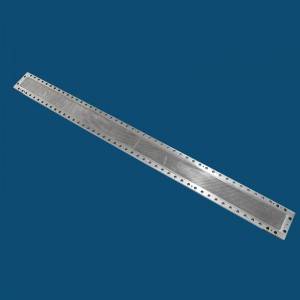

OEM Supply Surgical Medical Mask - spunbonded spinneret – Shengshuo

spunbonded spinneret,has at least ten thousands of rounded ultra micro hole,made from forging SUS630 or SUS431,able to produce the fabric which the width from 1600-3200mm,diameter can be done from 0.25-0.5mm,L/D from 1:10-1:15. it attaches to the spunboned header,melted material going from the header then through the air duct and the distributor,then going into the spinneret,until to the chemical fiber.it has to be cleaned every 45 days to 60 days. -

China wholesale Nano Woven Fabric - non-woven fabric – Shengshuo

non-woven fabric,width can be done from 27cm to 320cm,especially the melt blown fabric, is the core technic of the medical protection and filtration industry.the quality of the non-woven fabric depends on good quality material and good quality production line. -

Low MOQ for Pp Melt Blown Fabric T Die - non-woven fabric production line – Shengshuo

non-woven fabric production line,consists of feeder/extruder/filter/metering pumps/heater/die header/spinneret/regular box/drafter/diffuser/electret treatment/suction/hot rolling/winder/rewinding maching/slitting machine,specially designed for different kinds of non-woven fabric(fabric S,fabric M,fabric SMS,fabric SMMS),widely used in filtration/separation/medical protection industry. -

Good User Reputation for Melt Spinning Polyester - PP filter – Shengshuo

200mesh-400mesh(75um-38um),customrization. It attaches between the extruder and the header,impurity substance can be filtered out before going to the header,able to protect the spinneret & improve the effiency & improve the fabric quality -

Free sample for Melt-Blown Machine Lines - melt blown header – Shengshuo

hanger type melt blown header,designed for melt blown fabric producing,fabric width can be done from 27cm to 320cm,meet various kinds of requirements,made by foring SUS630 or SUS431,material melted by hot oil or electric heater then going into the header,then pushed into the spinneret through the air ducts. -

Hot sale Factory Spinning Production Line - spunbonded spinneret – Shengshuo

spunbonded spinneret,has at least ten thousands of rounded ultra micro hole,made from forging SUS630 or SUS431,able to produce the fabric which the width from 1600-3200mm,diameter can be done from 0.25-0.5mm,L/D from 1:10-1:15. it attaches to the spunboned header,melted material going from the header then through the air duct and the distributor,then going into the spinneret,until to the chemical fiber.it has to be cleaned every 45 days to 60 days. -

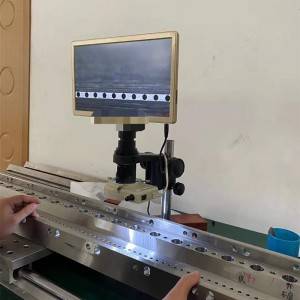

Wholesale Hollow Fiber Spinneret For Mask Machine - spinneret detector – Shengshuo

spinneret detector,consists of the high power microscope and LCD.as time goes on,the ultra micro hole might be blocked by the impurity substance,in that way the quality of the chemical fiber will be compromised,in order to improve the fiber quality,spinneret can be detected randomly. -

Factory making Picture Of A Spinneret - segment-pie spinneret – Shengshuo

segment-pie bi-component fiber,is a kind of chemical fiber for traditional woven fabric,widely used for the apparel.The quality requirement to the spinneret will be higher than the one used for the non-woven fabric.the segment-pie spinneret we produced has gained the good feedback from the market,and was sold to south-east asia. -

Europe style for Sms Fabric Technology - melt blown header – Shengshuo

hanger type melt blown header,designed for melt blown fabric producing,fabric width can be done from 27cm to 320cm,meet various kinds of requirements,made by foring SUS630 or SUS431,material melted by hot oil or electric heater then going into the header,then pushed into the spinneret through the air ducts. -

China Factory for Fiber Spinneret - spunbonded header – Shengshuo

spunbonded header,is also called spinning box,designed for spunbonded fabric producing,fabric width can be done from 160cm to 320cm,meet various kinds of requirements,made by foring SUS630 or SUS431,material melted by hot oil or electric heater then going into the header,then pushed into the spinneret through the air ducts. -

Reasonable price Spinneret And Spin Pack - spunbonded spinneret – Shengshuo

spunbonded spinneret,has at least ten thousands of rounded ultra micro hole,made from forging SUS630 or SUS431,able to produce the fabric which the width from 1600-3200mm,diameter can be done from 0.25-0.5mm,L/D from 1:10-1:15. it attaches to the spunboned header,melted material going from the header then through the air duct and the distributor,then going into the spinneret,until to the chemical fiber.it has to be cleaned every 45 days to 60 days.