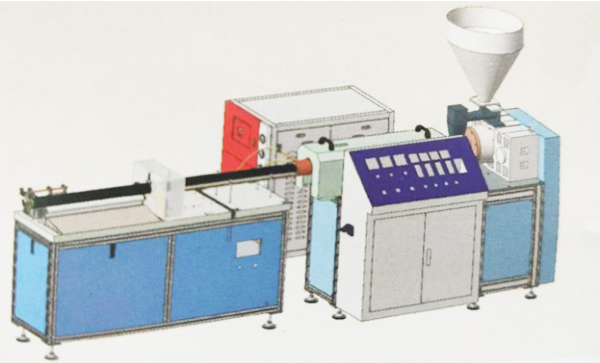

| Item | Continuous sintering equipment |

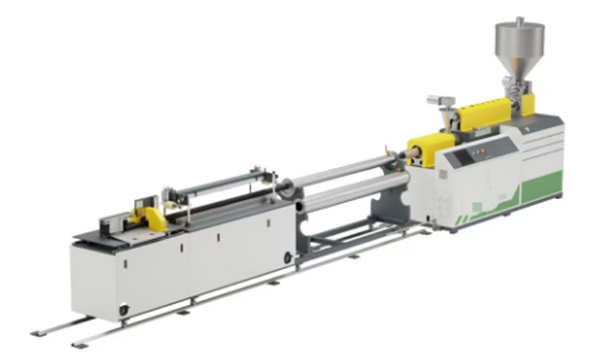

Traditional Extruded equipment |

| Capacity/24H | 500~600KG/24H | 420~450KG/24H |

| Applicable Activated carbon | Coal carboncoconut carbonnut shell carbon

|

Coal carboncoconut carbonnut shell carbon

|

| Applicable binder | UPE | LPE |

| Dust on site | NO Dust, Good Environment | Too much dust , Bad environment |

| Operating | Easy operating, stability, and Intelligent | Normal Human operating |

| Process and product quality | UPE has no fluidity when melted, presenting a semi transparent rubber like high viscosity elastic state, which can avoid blocking the pores of activated carbon and improve the porosity of the filter element.Reduce flow resistance, prevent excessive compaction of the filter element causing a decrease in porosity, while ensuring the mechanical strength and filtration performance of the filter element.The continuous injection sintering method has low energy consumption and high efficiency, which is superior to the traditional molding sintering method. | LPE as a binder can block the pores of activated carbon and affect its filtration performance. If the binder content is too low, powder leakage may occur during the adsorption process; Excessive content of filter cartridge binder can melt and encapsulate activated carbon, block the pores of activated carbon, significantly reduce the specific surface area of activated carbon, and greatly reduce its adsorption, decolorization, odor removal and other performance |

Post time: Feb-11-2025